Flexitank Market Growth and Insights: A Promising Future for Liquid Bulk Transport

As industries evolve, so does the demand for more efficient and cost-effective solutions in Liquid Bulk Transport. Flexitanks, large, flexible containers used for transporting liquids, are gaining significant traction in the market. The global flexitank market is set for significant growth. Demand is rising across industries such as food, chemicals, pharmaceuticals, and agriculture. This blog explores the market’s growth prospects and future trends. It also highlights how flexitanks address common bulk liquid transport challenges.

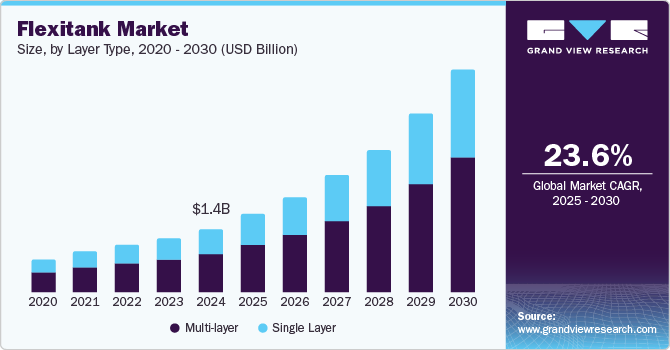

Promising Growth in the Global Flexitank Market

According to recent Grand View Research, the global flexitank market is expected to reach USD 1,357.3 million by 2024, with a projected growth rate of 23.6% CAGR from 2025 to 2030. This rapid expansion is driven by industries seeking efficient, eco-friendly, and cost-effective solutions for transporting bulk liquids. With their ability to fit inside standard shipping containers, flexitanks offer a space-saving and flexible alternative to traditional transport methods like drums, IBCs, and ISO tanks.

One of the primary drivers for this market growth is the demand for safe and reliable bulk liquid transport solutions. Flexitanks offer superior advantages such as reduced spillage risks, minimized contamination, and enhanced cost-efficiency. In particular, industries like food and beverage, oil, and chemicals are increasingly adopting flexitanks to streamline their shipping operations and reduce costs.

Layer Type Insights: Enhancing Durability and Safety

Flexitanks are made from multi-layered materials, typically polyethylene (PE) or polypropylene (PP), designed to handle different types of liquids. These layers provide strength, durability, and protection from external factors such as temperature fluctuations and contamination. The number of layers used in manufacturing flexitanks plays a crucial role in the strength and performance of the tank.

Single-layer flexitanks are often used for less sensitive liquids, whereas multi-layer flexitanks provide extra protection for more sensitive liquids, such as edible oils and pharmaceuticals. The use of advanced materials and innovative manufacturing processes ensures that the contents are safely transported with minimal risk of leakage or spoilage.

Credit: Grand View Research

Application Insights: Versatility Across Industries

Flexitanks have a wide range of applications across multiple industries. The food industry, especially for the transportation of edible oils (like palm oil, coconut oil, and vegetable oils), benefits from the flexibility and safety that flexitanks provide. In addition to oils, flexitanks are also used for the transportation of juices, sauces, water, beer, wine, and other bulk liquid items.

- Palm Oil Transportation: With palm oil being one of the most widely traded edible oils in the world, flexitanks offer a cost-effective solution for transporting this high-value product. Their airtight design ensures that palm oil remains free from contamination, preserving its quality during transit.

- Juices and Beverages: Flexitanks offer an excellent solution for the transportation of fruit juices and beverages. With a strong and flexible design, these tanks ensure that the product remains uncontaminated and maintains its freshness, even during long-distance transport.

- Bulk Liquid Transport for Chemicals and Pharmaceuticals: Flexitanks are also increasingly being used for the safe transportation of industrial chemicals and pharmaceutical liquids. These liquids often require stringent safety measures to prevent leaks and contamination, and Flexitanks meet these needs with their robust, leak-proof design.

Asia Pacific Flexitank Market Trends

The Asia Pacific region is witnessing significant growth in the flexitank market, driven by expanding industries like agriculture, chemicals, and food. Countries such as India, China, and Japan are increasingly adopting flexitanks as a reliable and cost-effective transport solution for bulk liquids. The growing demand for eco-friendly solutions, combined with the need for efficient supply chains in emerging markets, is further fueling the market’s growth. Flexitanks are particularly popular in the region for transporting palm oil, edible oils, and chemicals, where large quantities need to be shipped safely and efficiently.

How Fluid Flexitanks Solve Bulk Liquid Transport Challenges

Fluid Flexitanks provide solutions to many common challenges faced in bulk liquid transportation, such as:

- Cost Efficiency: Flexitanks help businesses save on shipping costs by offering more space inside shipping containers and reducing the need for additional packaging materials like drums or IBCs.

- Safety and Quality Assurance: Flexitanks are designed to keep liquids intact and uncontaminated during transit. Their airtight design ensures that the contents remain free from exposure to air, moisture, and contaminants.

- Eco-Friendly Solutions: With sustainability becoming a global concern, flexitanks provide a greener alternative to traditional transport methods. Made from recyclable materials, flexitanks reduce the environmental impact of packaging waste.

Conclusion

The flexitank market is set for significant growth in the coming years, driven by the increasing demand for safe, efficient, and cost-effective bulk liquid transport solutions. With advanced materials, multi-layer designs, and versatile applications across industries like food, chemicals, and pharmaceuticals, flexitanks offer unparalleled benefits.

For businesses looking to optimize their shipping operations, especially in the Asia Pacific region, investing in flexitanks can be a game-changer. They help reduce costs, enhance safety, and contribute to environmental sustainability, making them a preferred choice for bulk liquid transport.

Flexitanks are used for a variety of liquids, including edible oils (palm oil, coconut oil), juices, water, beer, wine, chemicals, and pharmaceuticals.

Flexitanks are designed with airtight seals and advanced materials to prevent contamination and temperature fluctuations, ensuring that liquids remain safe and fresh.

Yes, flexitanks are made from recyclable materials, minimizing waste and supporting sustainable transport practices.

Flexitanks maximize shipping container space, allowing for more liquid to be transported with fewer shipments reducing overall transportation costs.

Flexitanks are more cost-effective, safer, and environmentally friendly than drums, IBCs, and other traditional containers, making them the preferred choice for bulk liquid transport.