Container Liners Are Ideal For Pharma Companies Shipping Pharmaceutical Products

Pharmaceutical companies indulge in transportation of medicines and other pharmaceutical products often faces huge amount of challenges maintaining the quality during transit. There are many factors that play a part in raising the challenges for pharmaceutical companies they are natural elements like weather, temperature, salty atmosphere, sanitary conditions and more. It is because of this reason pharmaceutical companies looked for a solution that could help them overcome the challenges during the transit. The solution came in form container liners, which contributed the pharmaceutical companies with the entire requirement they need to overcome the challenges.

Let’s take a look at what container liners are and how they help pharmaceutical companies during the transit.

What are Container Liners?

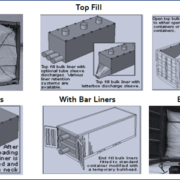

Container Liners are protective packaging bags made up of many different types of materials that are ideal for the purpose of storage and transportation of dry goods and products in a cargo. Container liners can be used for transportation of products even beyond the borders of the country through shipping, while ensuring safety of product across natural calamities and changes, while being compatible with the basic necessities of the product. The main use of container liner is to ensure safe packaging of products for the purpose of transportation. The container liner works as an ideal itinerary to create gap between the container and product in order to keep it safe from any type of reaction with the container. Further container liner provides assistance in temperature and other factorial control for the product within the container to keep it safe from getting spoiled or damaged from any natural element or fluctuations in surrounding environment. Thus clearly reflecting how container liner plays crucial role in safe keeping of the product during transit. However, these prospective advantages provided by the container liner depends on the types used based on the requirement of the product, clearly reflecting that selecting the type of container liner must be made wisely taking into consideration all external factors to get the maximum benefit out of the container liners. Production of container liners from various materials makes it ideal utility for storage and transportation of all types of goods in a controlled environment. This clearly highlights the wide variety of proposition that container liners bring in for industries in terms of storage and transportation of products.

It is because of this large variety of controlled approach and safety provided by the container liners they are widely used in pharmaceutical industry. Let’s take a look at how container liners contribute to pharmaceutical industry!

What Makes Container Liners ideal for Pharmaceutical Industry

There are many factors that play a crucial role in making container liners the ideal choice for pharmaceutical industry. Some of which are reflected as below:

Ability to Transfer Heat

Heat is transferred through three modes: conduction, convection and radiation or infrared. Radiation is main mode of all the three and other two are secondary and come to the forefront only when matter starts interfering with radiant heat transfer. All substances require transfer heat including air spaces. The container liners are manufactured in such a manner that they can transfer the heat using all the three processes allowing it be ideal utility of storage and transportation medium where any single temperature is required. This in turn makes it ideal for pharmaceutical industry.

Ability to control Emissivity Rate

When infrared rays strike on the surface of an object or matter the rays are absorbed and after that heat is produced on the object. The heated object transmits infrared rays from the exposed surface through radiation if the surface is directly exposed to air space. The radiation amount emitted is a function of Emissivity factor of the source’s surface. Emissivity is a rate at which the radiation is given off. Container liners outer layer being reflective helps in controlling the emissivity rate, which is good for the pharmaceutical products, as they are safeguarded from rapid temperature fluctuation.

Ability to Control Humidity

Container liners work like a woven laminate to provide complete humidity-controlled environment and sealed off temperature for cargoes. The liner is manufactured by using WPP fabric and has polythene sheeting. It is a preferable option for 20 and 40 feet container liner and protects the content inside by reflecting 97% of radiant energy. Thus creating moisture less environment within the container, which is ideal for pharmaceutical industry to protect medicines specially from getting damaged by moisture.

Protects Loss of Pharmaceutical products against Leakage and Spillage

The container liners are manufactured from flexible polymers as per the requirement and size of the containers. This allows the container liners play a vital role in the creation of an extra wall inside the container. This, in turn, helps in the safeguarding of the pharmaceutical products from loss in volume because of leakage or spillage. It is because any loss of pharmaceutical product during the process of loading, unloading and transportation accounting from leakage will automatically get collected in the container liners, which can then be collected in separate packaging ensuring safety of pharmaceutical product from loss in volume during transportation. This in turn also protect the pharmaceutical company from bearing additional cost required for cleaning or accidents that may happen from leakage or spillage.

Protect against Salty Weather

Container Liners are made from polymers and are usually zip tight locked to ensure that the nothing can enter the packaging including moisture. It is because of this reason even on long voyages across the sea; salty weather conditions cannot affect the pharmaceutical product on transit, thus making them absolutely safe from any type of alteration because of salty weather. It is because of this reason container liners are widely used across pharmaceutical industry.

Container Liners ensure sanitize environment

One of the most demanded critical factor that pharmaceutical industry look forward to achieve is a sanitize environment. It is because of this reason container liners plays wonders for Pharma industry when it comes to keeping a sanitize environment. The container liners are usually neutral in reactive nature along with thorough air tight protection against all natural elements. It is because of this reason the internal environment of the container remain thoroughly sanitized and protected against any kind of impurities with the usage of container liner, making them ideal for pharmaceutical industry.

So if you are into pharmaceutical business related to transportation of product and is looking for an easy and cheap solution to protect your product and overcome the challenges that transportation of pharmaceutical product carries, then the container liners are the ideal itinerary for your business. To know more about container liner or for business enquiry you can contact us at Rishi FIBC.

Why Choose Us

Rishi FIBC is one of the leading container liners manufacturers with business across 42 different countries providing premium quality products to the users. The container liners so manufactured by us meets all the necessary standards and quality parameters, thereby making sure that none of the users get even a single chance to complain. With our decades of experience and sheer level of expertise, Rishi FIBC makes sure to live up to the expectation of every user in the best possible manner. So what are you waiting for! Get in touch with us over our helpline number or our website to get proper guidance and fulfill your business inquiry related to container liners.